| |

| Why Choose A Toroidal

Transformer? |

|

|

| In the past,

only the most exotic power application justified the use

and cost of a toroidal transformer, as they were in

limited supply due to the cost of winding toroidals.

However, technical advances in winding and production

techniques have lowered the cost and increased the

availability of toroidal transformers, making them a

desirable and cost-efficient alternative to laminated

transformers in a wide variety of applications.

|

| |

| Benefits of Toroidal Transformer

Design |

|

|

Efficiency: The toroidal form

of transformer offers excellent efficiency for a given

size and weight.

The toroidal core provides

a virtually perfect magnetic circuit, eliminating the

inherent air gaps of conventional laminated-bobbin

transformers. Higher flux densities, along with full

utilization of the core area, result in a smaller

component-typically 50% of the size and weight of

laminated components. The overall efficiency of

toroidals is typically 90 to 95%, and with custom design

can be even higher. Due to the high quality, tightly

wound, grain-oriented silicon steel core, very low core

losses and off-load magnetizing currents can be

achieved, adding to the overall

efficiency.

Low

noise and low stray flux field: Because the

magnetic circuit is so complete, and due to the uniform

distribution of the windings over the core, a toroidal

transformer is very quiet in operation-with low or even

zero mechanical hum caused by magnetostriction. Toroidal

transformers also exhibit very low levels of

noise-inducing stray magnetic fields (typically 8 times

lower than laminated stack type transformers). This

makes the toroid the perfect choice for sensitive

electronic systems such as high-gain preamplifiers and

instrumentation.

Good

regulation: The winding configuration of

toroidal transformers results in very low leakage

inductance. This inductance is produced when a

percentage of the magnetic flux produced by the primary

is not utilized by the secondary, therefore not

generating any voltage-a common characteristic of

laminated stack transformers. Because toroidal winding

results in tight coupling, virtually all the flux is

utilized (and not left to radiate and interfere with

circuitry). This enables tight regulation, with off-load

secondary voltages lower than laminates. In addition,

lower copper loss results in less power being wasted as

heat.

Ease of

mounting: The majority of toroidal

transformers are mounted with one central screw,

speeding production time and lowering the parts count of

mounting hardware. For special applications, custom

mounting methods can easily be provided for greater

production efficiency.

Packaging versatility: A

toroidal transformer with specific characteristics can

be varied in height and diameter to meet product-design

requirements. This enables the transformer to meet

enclosure space constraints. Tall cylinder or flat disc

styles can be produced to meet retrofit space

requirements or low-profile

applications.

Markings: Avel Lindberg

Standard Toroidal Transformers comply with most of the

world's major safety standards (including UL506, UL2601,

UL1411, and UL1950) and are built under our UL- and

CSA-recognized design and construction files. Custom

designs can be manufactured to comply with most other

standards, whether European, medical, military, or

commercial. All Avel transformers are CE marked.

|

| |

| Guide To Transformer Selection and

Specifications - Introduction |

|

|

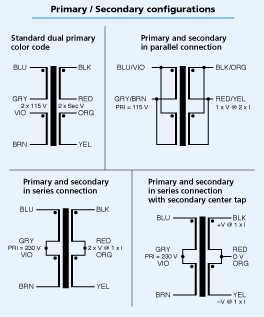

| Avel's standard

general-purpose transformers are available with dual

primary windings for operation at 50/60 Hz, and series

or parallel connection. They incorporate dual

secondaries that can be used in series, parallel or

independently, in a range of voltages and VA ratings to

suit most power and electronic

applications.

This combination of windings

enables one component to be specified both for domestic

use and for export to other countries where line

voltages differ, as well as providing several secondary

power configurations. If your application requires a

power supply configuration that cannot be met with our

standard range of transformers, our custom transformer

service is ready to design a transformer to your precise

needs. This may be just a slight modification to our

standard range or a unique custom

design.

The next few pages contain a

general guide to some of the criteria that should be

considered when specifying a custom

transformer. |

| |

| Guide To Transformers - Power

Rating |

|

|

| Transformers

are rated in Volt Amps (VA), which is the product of rms

AC voltage and rms AC current for a predominantly

resistive load.

Example

1:

A

heating element requires 4 Amps at

24 volts AC

and is to be driven from a 115 or 230v, 60 Hz mains

supply.

A 115 + 115v to 24v step down

transformer is therefore required, with a VA rating of 4

x 24 = 96 VA (100 VA will therefore be

suitable).

Example

2:

Two 50 watt Halogen Lamps are to be connected in

parallel, and require 12v AC to obtain full brightness.

A 115v fan is also required to be run, which draws 182

milliamps. This combination is to be driven from 115v 60

Hz supply.

A 115v step down transformer

with 2 separate secondary windings is therefore

required.

Secondary 1 should be rated

at 12v, 100 VA (8.33 Amps)

Secondary 2 should be

rated at 115 x 0.182 = 20 VA

The transformer

total rating is 100 + 20 = 120 VA

A

transformer supplying reactive or rectifier loads needs

to be rated according to the load characteristic. Our

engineers are pleased to offer guidance regarding

ratings for any application (see also rectifier

transformers). |

| |

| Guide To Transformers - Duty Cycle

|

|

|

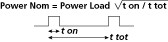

| If the load is

not continuous and is much shorter than the thermal time

constant (the time taken to reach steady on-load

temperature, which can be several hours), a smaller

transformer can often be specified. The following

formula is helpful in calculating the rating

needed.

Where: Power

Nom. = Nominal transformer rating

Power Load =

Actual power in the load

t on = Load on time

t tot

= Total cycle time |

| |

| Guide To Transformers - Operating

Frequency |

|

|

The operating

frequency determines the transformer size and weight for

a given output power-higher frequency generally means a

smaller transformer.

A transformer designed

for 60 Hz operation only will therefore be smaller and

lighter than one designed for 50/60 Hz operation, though

this size reduction will not be considerable for a

difference of only 10 Hz. However, a transformer for 400

Hz operation may be up to 80% smaller than a 50/60 Hz

transformer. It is important to specify the minimum

expected operating frequency of transformers, as

operation is possible above the designed frequency but

not below. |

| |

| Guide To Transformers - Primary

Configuration |

|

|

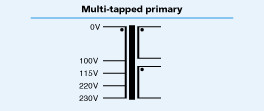

| It is

preferable to try to obtain the required secondary

voltages using separate identical primaries to be used

in series or parallel. For example, two identical 115v

50 Hz primaries would be connected in series to obtain

230v 50 Hz, or in parallel to obtain 115v, 50 Hz. This

arrangement is the most economical in both price and

transformer size. A more versatile arrangement would be

2 identical primaries of, for example, 0-100-115V. This

will provide 100, 115, and 230V, covering input voltages

for places such as Japan, USA, and Europe.

(The unused taps must then

be insulated well, as these will be at their stated

voltages above ground and to the other windings when the

transformer is in use.)

Another option (which

generally requires a larger and more expensive

transformer), is a multi-tapped or ladder

primary.

|

| |

| Guide To Transformers - Primary

Voltage |

|

|

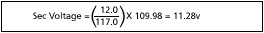

| The Primary

voltage(s) stated in standard transformer specifications

(or customer-specified in an inquiry) are the nominal

voltages. These voltages may vary during times when line

supplies are at heavy loads (nearly always around

dinnertime), or light loads (when most people are

asleep). Drops or rises in this voltage can be as much

as 10% of the nominal and vary considerably from country

to country. This change in voltage will be reflected on

the secondary voltage (on and off-load) by the standard

transformation relationship:

Example:

A toroidal transformer is rated at

12v and the primary is rated at 117v 60 Hz. The line

supply regulation is stated as ± 6% by the utility

company.

The secondary voltage when

the line is at its lowest voltage will be:

|

| |

| Guide To Transformers -

Regulation |

|

|

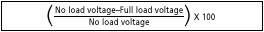

Transformer

regulation is a measure of the voltage rise on the

secondary due to off-load or light-load conditions with

the primary input voltage remaining constant. This

measure is expressed as a percentage of the secondary

voltage; for example, a transformer with 10% regulation

and rated at 12v at full load will have an off-load

voltage of 13.2v.

Regulation is calculated

as:

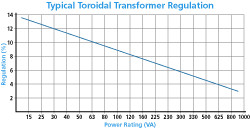

Due to the design

characteristics of transformers, regulation varies

inversely with power rating (VA) and is approximately

linear for any given loading on the secondary. In the

above example, if the load was 50% of full load, the

voltage would be 5% higher, or 12.6v. This regulation

figure must be borne in mind when designing rectifier

power supplies, etc. as it will affect the voltage

rating of reservoir capacitors, voltage regulators,

etc.

Custom transformers can be designed with

very low regulation figures but only at the expense of

size and weight, as larger cores and wire gauges must be

used. Following are some typical regulation figures for

standard transformer VA ratings.

|

| |

| Guide To Transformers - Temperature

Rise |

|

|

Avel's standard

toroidal transformers are designed for a temperature

rise of a maximum of 60ºC, and have a material rating of

Class A (105ºC), although the winding wire used has a

rating of Class F (155ºC) for additional reliability.

This temperature rise is above the ambient temperature

of approximately 30-35ºC.If a higher temperature rise

can be tolerated by surrounding components and

enclosures, then a reduction in transformer size may be

considered.

Avel can manufacture to most

standard temperature classes, although the cost of the

transformer will rise considerably due to the

higher-cost materials that would be required. It is

important to furnish expected ambient temperatures in a

custom inquiry for any temperature class, as the running

temperature of the transformer will be the ambient

temperature plus the transformer temperature

rise.

Below are some standard

temperature classes.

Insulation

Classes:

- Y = 90º C

- A = 105º C

- E = 120º C

- B = 130º C

- F = 155º C

- H = 180º C

|

| |

| Guide To Transformers - Capacitive

Shielding |

|

|

Transformers by

nature are wide band devices regarding stray signal

coupling. Where a transformer is required to operate in

electrically noisy environments, a conducting shielding

layer can be interposed between the primary and

secondary windings (or between individual secondaries)

to minimize the capacitance between them. This can

reduce (or even eliminate) some types of common mode

noise, but its effectiveness depends on the noise

characteristic as well as the transformer's overall

surface area.

This type of shield is

sometimes required to satisfy certain safety regulations

and circuit configurations. Capacitive screens add

layers and cost to a toroid's build, because if they are

required, a larger core may have to be specified with a

large enough inner diameter to complete the windings.

This type of shielding should supplement and not replace

the usual line filters and suppressor networks that may

be required for circuit operation or EMC

compliance. |

| |

| Guide To Transformers - Magnetic

Shielding |

|

|

Although

toroidal transformers emit minimal stray magnetic fields

by their nature, a certain amount will always be present

as with all magnetic devices. For the vast majority of

applications, toroidal emissions are far too low to

affect circuit operation, but there are some

applications that are especially sensitive.

These

include wideband, high-gain instrumentation and

preamplification, high-end audio, and high-resolution

CRT circuits. In this case, magnetic shielding can be

applied around the toroid in the form of a

high-permeability metal band. This can be Silicon Steel

for the majority of cases or Mu Metal for sensitive

applications. For extremely sensitive circuits, total

encapsulation in a steel can or case may be the only

option. There are ways to reduce emissions by design

(before any protection is added to the transformer), so

if your circuit is prone to magnetic interference,

please include this information in specifications when

requesting a quotation. |

| |

| Guide To Transformers - Inrush

Currents |

|

|

| Due to the

excellent magnetic circuit that toroidal cores create,

and also due to the remanence that results from the more

square hysteresis loop that these cores possess, high

inrush currents can be encountered when switching on

large toroidal transformers. These are higher than in

laminated stack transformers and can last for a few

half-cycles of the mains voltage. This is caused by the

core saturating for a split second and is quite normal.

However, this means that larger toroidals (1.5 KVA and

higher) should not be switched on without some

precautions.

It is recommended that

slow-blow (type T) fuses be used in the primary circuits

of all transformers over 100 VA. For larger toroids,

either NTC thermistors or circuit breakers designed for

motors and transformers (with type D delay

characteristics, for example) should be incorporated.

Simple relay-switched resistor soft start circuits can

also be used effectively, and a delay of between about

30 to 300 mS will usually work effectively (some relays

themselves have pull-in delays of approximately this

time). Soft start circuits of this kind should be

implemented with, and never replace, the proper circuit

protection provided by fuses or circuit breakers.

|

| |

| Guide To Transformers - Mounting

|

|

|

The standard

method of mounting toroidal transformers to a chassis is

with a dished steel washer, with the transformer

interposed between cushioning gaskets, with this

hardware held in place by a single bolt passed through

the central hole of the toroid. These mounting kits are

supplied with standard transformers. For other mounting

options, please see the custom

transformers.

Caution: The metal chassis should

not touch both ends of the mounting bolt. This causes a

shorted turn, which would overheat the transformer

rapidly and cause its destruction. |

| |

| Guide To Transformers - Varnishing

and Vacuum Impregnation |

|

|

| Avel offers

full vacuum and pressure varnish impregnation, as well

as envelope dipping with mold-resistant polymers and

protective barriers. Impregnation and dipping can be

carried out with either standard solvent-based coil

varnishes or solventless epoxy varnishes. Contact Avel

for further information, or where you feel you may have

an unusual environmental requirement. |

| |

| Guide To Transformers - Thermal

Protection |

|

|

| Thermal

protection can be built in to our toroidal transformers

in the form of thermal sensitive fuses and switches

(thermostats). These protectors are generally built

inline into the primary winding, and are in close

thermal contact with the windings. Thermal fuses are not

resettable and once blown cannot be replaced. Thermal

switches are designed to open at a set temperature and

will close again upon cooling, reforming the primary

circuit (with slight hysteresis). These protectors may

be required to satisfy certain safety approvals.

Customer specified protection can be added in the form

of Normally Open switches, as well as incorporation into

specific windings. Thermal protection always adds to the

cost of toroidals and can affect the transformer

geometry slightly. Our engineers are pleased to advise

on protection issues. |